In metal spinning, the forming roller usually moves very slowly while the mandrel and material rotate at high RPMs. Hence the products of metal spinning have been inherently limited to axisymmetric shapes that have circular cross sections around the rotation axis. Nonetheless, there has been a potential demand for products of non-axisymmetric shapes formed by metal spinning, e.g. tank ends, hoppers, exhaust pipes and lighting fixtures. Metal spinning is expected to be used more widely if it can be used to produce a variety of non-axisymmetric products.

Various methods were proposed for spinning non-axisymmetric products so far, such as products with elliptical cross section, products with eccentric or oblique axes etc. However, those methods generally required a specially designed spinning device for each shape.

Here we present metal spinning of non-axisymmetric products by applying force feedback control. A non-axisymmetric mandrel of a desired shape is used. The pushing force of the forming roller is controlled and the material is forced onto the mandrel. The roller follows the contour of the mandrel to fit the material to the mandrel. This enables a non-axisymmentric product of the same shape as the mandrel to be fabricated.

This method does not need a specially designed mechanism to cope with each cross section shape. Various non-axisymmetric shapes can be easily spun by replacing the mandrel. Since the shape of the product is determined by the shape of the actual mandrel, large amount of data on the 3-dimensional shape are not required for control.

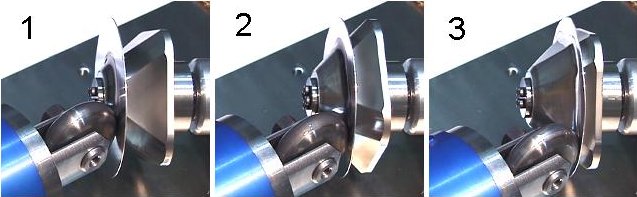

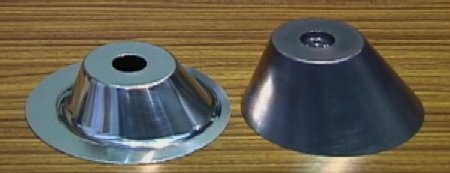

Two types of non-axisymmetric mandrels are prepared. Mandrel #1 is a conical mandrel with a 45 deg half angle which is partly machined by wire-cut EDM (Electrical Discharge Machining) into flat planes. Mandrel #2 is a cone with a 30 deg half-angle slanted by 10 deg and with the top and bottom wire-cut by EDM. The mandrel axis is eccentric and the cross section normal to the axis is elliptic. The above figure shows the forming process using Mandrel #1.

This figure shows the mandrels and the completed products. For both mandrels, the products tightly fit the mandrels and precisely formed into the non-axisymmetric shapes