Synthesis and

Thermoelectric

Properties

of Single-Crystal

Cobalt-Based Layerd

Oxides

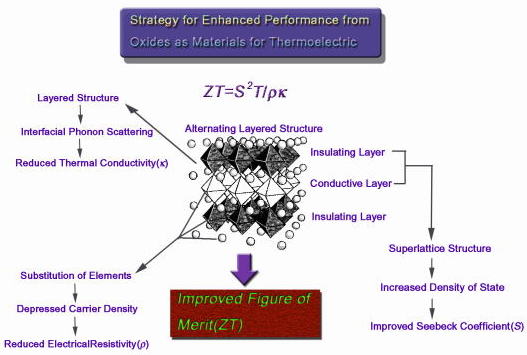

Introduction

At AIST

Kansai, our group is

active in R&D of

high-performance

thermoelectric

generators (devices for

conversion of heat

energy into electrical

energy), which utilize

oxide materials to

provide stable

functioning for long

periods of time at high

temperatures in air. In

exploring novel

thermoelectric

materials, our focus on

layered materials

composed of alternately

stacked conducting and

insulating layers (Figure

1.) led to a

ügfortuitousüh success

with the synthesis of a

single-crystal oxide

displaying extremely

high p-type (positive

hole conduction)

thermoelectric

properties, even at high

temperatures in air. The

single crystal

discovered is a layered

oxide with the

composition (Ca2CoO3)xCoO2

(Co-349).

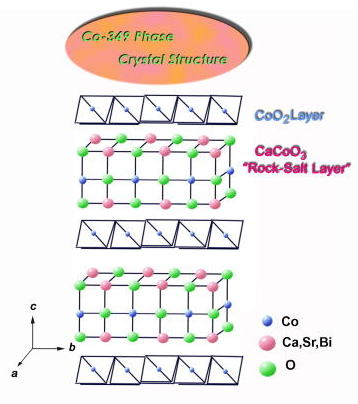

Figure 2 provides a

depiction of the Co-349

crystal structure. The

layered structure

possessed by this oxide

consists of two units

alternately piled one on

top of the other. One of

these units is a CoO2layer

with single Co atoms

surrounded by six O

atoms oriented as

edge-sharing octahedra.

The other is a Ca2CoO3

layer possessing a

rock-salt structure.

What follows is a report

on the method of

synthesis and

thermoelectric

properties of Co-349

single crystals.

Fig.1 Fig.2

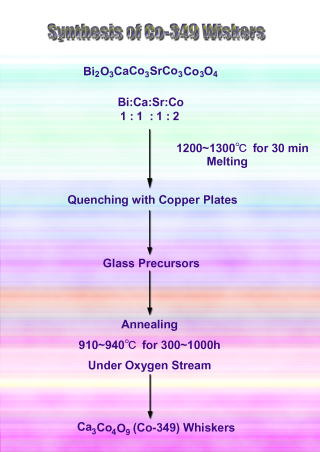

Preparation

Co-349 single

crystals were grown

using a glass annealing

method. (See

Figure 3) Bi2O3,

CaCO3, SrCO3

and Co3O4

powders used as starting

materials were mixed to

achieve an element ratio

of Bi:Ca:Sr:Co =

1:1:1:2, then melted at

1300üKC for 30 minutes in

air. The melted raw

materials were poured

and quenched by pressing

between two copper

plates at room

temperature to achieve

glass precursors for

whisker growth.

Annealing of glass

precursors at 920-930üKC

for 60-1000 hours under

an oxygen stream yielded

single-crystal

ügwiskers.üh

Figure 4 presents

photographs of Co-349

whiskers taken using a

scanning electron

microscope (SEM). The

ribbon-like Co-349

whiskers were typically

50-200 â╩m in

width, 1.0-5.0 â╩m

in thickness and 0.1-1.2

mm in length. The broad,

well-grown plane of the

whiskers corresponded to

the ab-plane and

the thickness direction

was parallel to the c-axis.

Typical whisker

composition was Ca1.3Sr0.3Bi0.3Co2Ox

with Sr and Bi

substituting for the Ca

component. The c-axis

length calculated from

x-ray diffraction

patterns was 10.78ü.

Fig.3

Fig.4

Results

Figure 5 presents a

photograph of a

cross-section of a

Co-349 whisker taken

with a tunneling

electron microscope

(TEM). From this image,

it became clear that the

Co-349 phase possessed a

layered structure

stacked along the c-axis.

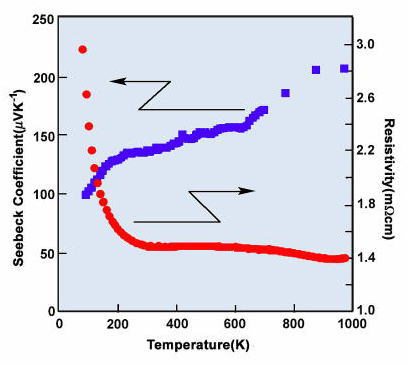

Figure 6 shows the

temperature dependency

of the Co-349 whiskerüfs

Seebeck coefficient (S)

and electrical

resistivity (â¤).

S is seen to

increase and ⤠to

decrease with rising

temperature. At

temperatures of 873 K

and over, S was 200 â╩V/K

or greater. Conversely,

low ⤠values of

1.4-1.5 mâÂéâm were also

recorded.

Fig.5

Fig.6

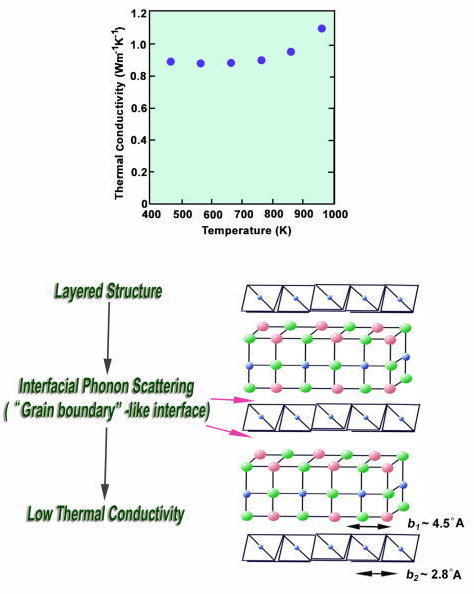

While

the thermal

conductivity(â╚)

of the Co-349 whiskers

could not be measured

directly due to the

small size of the

whiskers, â╚ of

sintered polycrystalline

material with the same

composition was found to

be at low levels of

around 1.0 Wm-1K-1

at 473-973 K. (See

Figure 7.) This is

thought to stem from

Co-349üfs layered

morphology. A misfit, at

the interface between

the CoO2 and

rock-salt layers of the

Co-349 lattice exists,

which causes phonon

scattering thus impeding

lattice thermal

conductivity. The figure

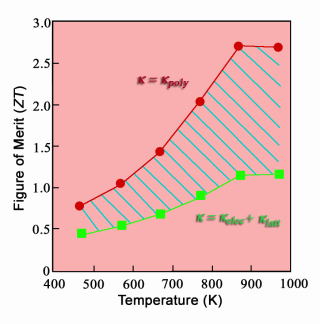

of merit (ZT) of

the Co-349 whisker was

calculated to be 2.7 at

973 K using the â╚

obtained from the

polycrystalline sample.

(Seeüť

in

Figure 8.) Generally

speaking, however, the

â╚ of a

single-crystal material

should be larger than

that of a sintered

polycrystalline one. At

this juncture, we

derived ZT of

Co-349 whiskers by

calculation of â╚

(= â╚elec+

â╚latt)

using the thermal

conductivity contributed

by the lattice (â╚latt),

which was estimated from

â╚ of the

polycrystalline

material, and the

thermal conductivity

contributed by the

charge carriers (â╚elec),

which was calculated

from the

Wiedemann-Franzüfs low.

(Seeüí

in

Figure 8.) Actual

whisker ZT values

are indicated in the

figure by oblique lines

producing a shaded area

between these two

parameters. As a result,

it became clear that

this oxide possesses

highly outstanding

thermoelectric

properties at high

temperatures in air, as

seen by Co-349 whisker

ZT of 1.2 and over

at temperatures of 873 K

and above.

But

what is it that gives

the Co-349 phase its

exemplary thermoelectric

properties? While the

answer still not

entirely clear,

comparison with Na2CoO4,

which possesses a

structure similar to

Co-349, leads us to

believe that something

in the rock-salt layer

is amplifying the

Seebeck coefficient.

Furthermore, thermal

conductivity is reduced

at layer interfaces. So

what we do know is that

different parts (lattice

and layer interfaces)

within the Co-349

crystal possess

different functions

(reduction of thermal

conductivity and

amplification of Seebeck

coefficient), which

complement each other

superbly, thus realizing

exceptional

thermoelectric

properties. In this

sense, Co-349 is the

very model of AIST

Kansaiüfs üglattice

compositeüh approach to

materials design.

Fig.7

Fig.8

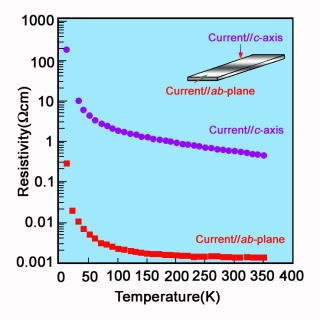

The

Co-349 material

developed thus far

through our research

contains no poisonous or

uncommon elements, and

is chemically stable

even at high

temperatures in air.

This means that it is

highly suited to

thermoelectric power

conversion using

high-temperature waste

heat as an energy

source. In order to

fabricate thermoelectric

generators using Co-349,

from hereon it will be

necessary to develop

large single crystals or

polycrystalline

materials possessing the

same thermoelectric

properties as seen in

the single-crystal

samples. The ZT

of Co-349

polycrystalline samples

prepared by solid-state

sintering was shown to

be one order of

magnitude lower than

that of the whiskers.

The origin of this is

the two-dimensionality

of â¤. (See

Figure 9.) While

⤠along the ab-plane

(â¤ab)

is low, as shown in

Figure 6, ⤠along

the c-axis (â¤c)

is 500-1000 times higher

than that of â¤ab.

As a result of this

two-dimensionality, in

polycrystalline samples

⤠is approximately 10

times higher than â¤ab

in the whiskers, and

ZT is thus one order

of magnitude lower. In

order to obtain

polycrystalline

materials with â¤

on the order of that

possessed by the

whiskers, crystal grain

orientation will need to

be aligned along the

ab-plane.

Melt-growth methods or

sintering methods under

uni-axial pressure, such

as hot pressing, are

thought to be an

effective as means of

production for this

purpose.

Fig.9

With

the discovery of Co-349,

practical application of

thermoelectric power

conversion utilizing

high-temperature waste

heat, thus far presumed

to be an energy source

confined to the realm of

dreams, has now become a

reality. The objective

from hereon will be to

develop n-type

thermoelectric oxide

materials, and solve

problems related to

technical factors, such

as electrodes, in

fabricating generators

for the purpose of

realizing thermoelectric

power generation from

high-temperature waste

heat.

References

R. Funahashi et al, Jpn.

J. Appl. Phys. 39 (2000)

L1127.

|